Key Takeaways

- Hydrostatic testing is essential for verifying the strength and leak-resilience of water mains.

- Strict adherence to up-to-date standards ensures reliable and repeatable results, as well as regulatory compliance.

- Detailed preparation and systematic procedure significantly increase test effectiveness and accuracy.

- Addressing environmental responsibility during testing is increasingly important for utilities and contractors.

Ensuring the reliability and safety of water distribution systems is fundamental to public health. Hydrostatic testing plays a crucial role in verifying that water mains are structurally sound and leak-free prior to becoming operational. From selecting the proper equipment to ensuring compliance with the latest standards, every phase of the process must be carefully managed. For professionals tasked with testing, using the right hydrostatic test pump not only ensures compliance but also enhances accuracy, offering confidence that water infrastructure will perform as required for years to come.

This comprehensive approach safeguards infrastructure investments, helps meet regulatory obligations, and significantly reduces the risk of failures that could disrupt communities. As industry standards evolve, so too must the methods and attention given to hydrostatic testing, along with its environmental impact.

Understanding Hydrostatic Testing

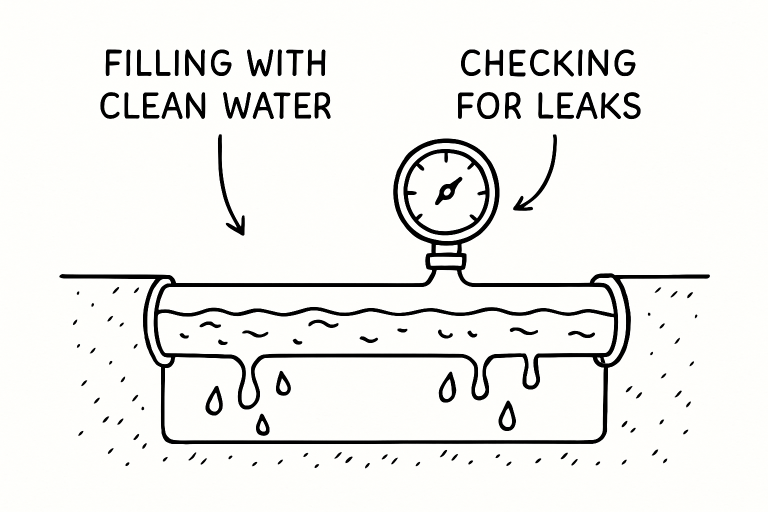

Hydrostatic testing is a process in which a pipeline is filled with water, subjected to a specific pressure, and monitored to detect any loss of pressure that may indicate a leak or structural issue. This test is used on both new installations and existing lines after repair, and is mandated by utilities worldwide to ensure assets perform reliably under normal and extreme conditions.

During the test, highly calibrated pressure gauges and other monitoring equipment track any pressure drops over a specified period. Even minor leaks can be detected, identifying faulty pipes or joints before the system is put into service.

Recent Standards and Regulations

In March 2024, Water UK introduced Water Industry Standard 4-01-03, which revolutionized the way pressure testing is conducted on polyethylene (PE) water mains. The significant updates contained within the standard include:

- Ensuring water mains are at ambient pressure before pressurization for accuracy.

- Enforcing a zero-tolerance approach to pre-pressurization, ruling out early ramping of pressure.

- Requiring a stabilization period of two to three hours between filling and raising pressure, which allows water temperature to match ambient conditions and eliminates skewed readings from thermal expansion.

- Reducing permitted air content from 8% to 4% to ensure that air pockets do not distort pressure readings or mask leaks.

These measures collectively enhance the reliability of testing, minimize false positives or negatives, and align with global best practices as outlined by organizations such as the American Water Works Association.

Preparation for Hydrostatic Testing

Detailed preparation is crucial. Testing failures, unnecessary water waste, and additional downtime often result from overlooked steps during setup. The most critical aspects of preparation include:

- Equipment Inspection: Verify that all devices, including pumps, hoses, and gauges, are functioning correctly, accurately calibrated, and free from defects.

- Pipeline Cleaning: Remove any debris or foreign objects within the pipeline to prevent blockages or erroneous readings.

- Air Removal: Carefully purge air using properly positioned vents. Even a small amount of trapped air can lead to inaccurate or failed tests.

- Correct Gauge Selection: Use pressure gauges with a scale that is 1.5 to 3 times the anticipated test pressure. This ensures precise measurements and minimizes the risk of gauge damage.

According to industry experts, improper preparation is a significant contributor to the majority of unsuccessful hydrostatic tests, resulting in wasted time and resources.

Conducting the Hydrostatic Test

Conducting the test itself is a systematic process that must follow industry protocols:

- Filling: The pipeline is filled gradually with clean water and left to acclimatize until the water reaches the same temperature as its surroundings.

- Pressurization: Slowly increase the pressure to the specified test level, adhering to ramp-up guidelines. The pressure is then maintained at a steady level for the required time interval, with precise readings taken throughout.

- Monitoring: Constantly review all pressure gauge readings for drops or unusual fluctuations, any of which may signal leakage or weakness.

- Inspection: Walk or visually inspect the length of the main, particularly at fittings and joints, for signs of leakage or sweating. Immediate corrective action should be taken if any issues arise.

Dealing with Test Failures

Test failures are not uncommon, especially on new installations or repaired mains. When evidence of a leak is found:

- Depressurize the system safely and promptly, following manufacturer and utility guidelines.

- Methodically inspect the main—often utilizing tracer dye, acoustic listening, or cameras if the leak is hidden.

- Repair the identified defect using approved methods and repeat the hydrostatic test to verify that the repair holds under pressure.

Thorough documentation of the repair and retest results should be retained for regulatory and insurance purposes.

Environmental Considerations

Environmental stewardship is a vital part of every hydrostatic test. Measures to protect ecosystems and responsibly manage water use during testing include:

- Always use potable or dechlorinated water for filling and testing. Quality of the water prevents contamination and meets regulatory safety thresholds.

- Dispose of water correctly and never release test water directly into storm drains or bodies of water without requisite treatment and environmental approvals.

- Consider using portable water treatment or recycling test water where feasible to minimize waste on large or repeated projects.

Awareness and adherence to local environmental regulations are as essential as technical compliance when conducting pressure tests.

Conclusion

Hydrostatic testing remains indispensable in validating the durability and safety of water mains, positively impacting public health and resource sustainability. By embracing the latest standards and meticulous procedures, water industry professionals and utility contractors can identify potential weaknesses before they pose risks to infrastructure or the environment. Proper planning, adherence to technical details, and mindful resource management ensure that hydrostatic pressure tests deliver both safety and long-term value.