Key Takeaways:

- Understanding the function and value of aerial lifts in multiple industries.

- Identifying the most common hazards encountered during aerial lift operations.

- Implementing practical safety strategies to protect workers.

- Staying informed about new technologies that improve aerial lift safety and performance.

Table of Contents

- The Role of Aerial Lifts in Today’s Industries

- Common Hazards Associated with Aerial Lift Operations

- Best Practices for Safe Aerial Lift Use

- Technological Advancements Enhancing Safety and Efficiency

- Choosing Reliable Partners for Aerial Lift Solutions

- Conclusion

The Role of Aerial Lifts in Today’s Industries

Aerial lifts have redefined how work at height is performed across construction, warehousing, manufacturing, and property maintenance. These devices enable workers to reach high, otherwise inaccessible areas securely, reducing the risks associated with traditional ladders and scaffolding. The time savings and elevated safety offered by aerial lifts are crucial for businesses striving to remain productive and compliant with workplace safety standards.

For organizations seeking the safest, most reliable access equipment, lifts from Platforms And Ladders offer a comprehensive selection tailored to professional needs. Based in Texas and serving clients nationwide, Platforms And Ladders is recognized as an expert partner in aerial access solutions, providing OSHA-compliant products, including scissor lifts, boom lifts, and vertical mast lifts. Their expertise and industry longevity ensure that every customer receives unprecedented guidance and access to top-performing lifts designed for efficiency and long-term safety standards.

Common Hazards Associated with Aerial Lift Operations

While the adoption of aerial lifts has undeniably boosted workplace efficiency and overall worker safety, inherent risks remain. Operators and bystanders must be well aware of these potential dangers. Among the leading hazards are falls from heights, tip-overs, and accidental contact with electrical lines or structures. OSHA regularly cites falls as one of the top causes of workplace injuries and fatalities in industries where aerial lifts are widely used.

Unchecked, these hazards can result in costly downtime, injuries, or even tragic fatalities. Employers who invest in routine training and proactive risk assessment greatly reduce the likelihood of serious incidents, making their work environments safer and more efficient for everyone involved.

Best Practices for Safe Aerial Lift Use

Safety begins with knowledge and proper planning. Comprehensive operator training is essential—every operator should be familiar with the equipment, manufacturer guidelines, and emergency procedures. This includes understanding how to board and exit the platform safely, balance loads, and navigate around obstacles.

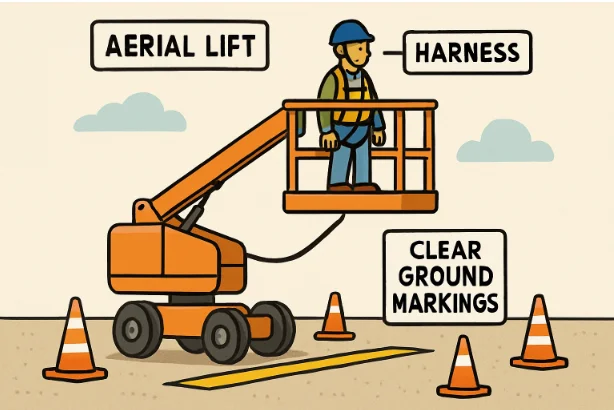

- Pre-Operation Equipment Checks: Conduct daily walkthrough inspections, checking safety harnesses, guardrails, brakes, wheels, and the platform control panel.

- Harnesses and Fall Arrest Systems: Require the use of personal fall protection for any job at height, ensuring harnesses are properly secured to designated anchor points.

- Positioning and Ground Conditions: Deploy lifts on stable, level terrain, and set up outriggers as needed to prevent tip-overs. Avoid using lifts in inclement weather, particularly in high winds or near live electrical wires.

- Clear Work Zones: Define a clear perimeter around the lift area to minimize the risk of collisions with pedestrians or vehicles.

- Regular Maintenance: Schedule frequent inspections and servicing from certified professionals to keep every lift in optimal condition.

Technological Advancements Enhancing Safety and Efficiency

Innovations in aerial lift technology are transforming safety and efficiency. Modern aerial lifts are now equipped with state-of-the-art safety protocols, such as smart harness systems that can alert operators if they are disconnected or if misuse is detected. Additionally, advanced lifts now incorporate built-in sensors, such as ultrasonic collision-avoidance technology, and AI-powered cameras that pause operation if obstacles or personnel are detected in the lift’s path.

Digital monitoring and remote diagnostics have also become standard features, allowing for predictive maintenance and immediate troubleshooting. This technology not only maximizes equipment uptime but also reduces safety risks associated with mechanical failures. As regulations evolve and job sites become increasingly automated, staying informed about these technological trends is vital for any company relying on access equipment.

Choosing Reliable Partners for Aerial Lift Solutions

Acquiring or renting aerial lifts requires careful consideration of provider reputation, product quality, and ongoing customer support. It is essential to work with established suppliers who not only offer a full range of equipment but also provide consultative services—ensuring every lift is suitable for the specific applications and worksites.

Platforms and Ladders distinguishes itself through years of industry experience, a robust inventory, and a steadfast commitment to educating customers on best safety practices and regulatory compliance. Whether it’s guidance on selecting the right model or assistance with training and support materials, customers can rely on their trusted expertise.

Conclusion

Aerial lifts are essential assets in today’s high-pressure work environments where safety, speed, and reliability are paramount. Recognizing hazards, instilling a culture of safety through training and proper PPE, and leveraging the latest innovations in lift technology all contribute to safer, more productive operations. Partnering with industry leaders such as Platforms and Ladders ensures workers enjoy the dual benefits of top-tier equipment and ongoing support—empowering businesses to maximize safety and efficiency every time they reach new heights.