Achieving and maintaining top-tier quality in pharmaceuticals is no small feat. With lives depending on the effectiveness and safety of every product, the stakes couldn’t be higher. From rigorous quality assurance practices to cutting-edge technology, every step in the pharmaceutical production process demands precision and adherence to the highest standards. This blog explores key strategies that ensure excellence in pharmaceutical quality, offering insights into best practices for sustaining superior standards.

What Is Top-Tier Quality in Pharmaceuticals?

Top-tier quality in pharmaceuticals refers to meeting or exceeding the highest industry standards for safety, efficacy, and consistency in drug development and manufacturing. It involves ensuring that every product, batch, and process functions in strict compliance with regulatory guidelines while consistently fulfilling patient needs. But quality isn’t just about meeting compliance benchmarks; it’s a commitment to protecting public health and building trust with healthcare providers, regulatory bodies, and, most importantly, patients.

Whether through stringent quality assurance programs, advanced technologies, or ongoing training efforts, achieving superior quality in pharmaceuticals demands a proactive and collaborative effort.

The Importance of Quality Assurance (QA)

Ensuring quality in pharmaceutical manufacturing hinges on robust quality assurance systems. QA goes beyond inspecting finished products; it builds a culture of prevention and consistency across the entire production lifecycle. Here’s why it matters:

- Patient Safety: Pharmaceuticals directly impact human health. Even the slightest deviation in quality can lead to adverse health outcomes, legal consequences, or a loss of trust.

- Brand Reputation: Quality issues don’t just affect patients. They can lead to massive recalls, tarnishing a company’s credibility and long-term viability in the market.

- Regulatory Compliance: Failing to meet quality standards can result in fines, production halts, or bans on particular products.

Key QA Processes

A strong QA framework includes:

- Establishing Standard Operating Procedures (SOPs): SOPs lay the foundation for consistent processes, leaving no room for human error.

- Regular Audits: Performing rigorous internal and external audits ensures adherence to established standards.

- Risk Management: Assessing risks in every stage of the supply chain helps pre-empt issues before they arise.

By embedding quality into every step of production, companies can ensure both compliance and customer satisfaction while safeguarding their reputation in an increasingly competitive industry.

Regulatory Compliance and Standards

The pharmaceutical industry is perhaps one of the most heavily regulated sectors in the world for good reason. Regulatory compliance means meeting the specific guidelines established by governing bodies like the FDA (U.S.), EMA (Europe), or MHRA (UK). These standards ensure that pharmaceuticals are produced safely and consistently, reducing potential harm to the public. Failure to adhere to these strict requirements can have devastating consequences, including product recalls, fines, or even the closure of facilities.

The Role of Professional Inspection

Compliance extends to ensuring that work environments meet stringent cleanliness and sterility standards, especially in aseptic manufacturing processes. This is where cleanroom consultants play a pivotal role. They guide pharmaceutical companies in designing, validating, and maintaining contamination-free environments. From HVAC systems to gowning procedures, these consultants ensure all systems function seamlessly, safeguarding product quality from external contamination.

Key Global Standards in Pharmaceuticals

- Good Manufacturing Practices (GMP) set the framework for safe and consistent production processes.

- ICH Guidelines (International Council for Harmonization) define standards for quality, safety, and efficacy.

- ISO Standards offer benchmarks for specific processes, such as lab testing or cleanroom environments.

By strictly adhering to these guidelines, pharmaceutical companies not only ensure legal compliance but also demonstrate a firm commitment to patient welfare and trust.

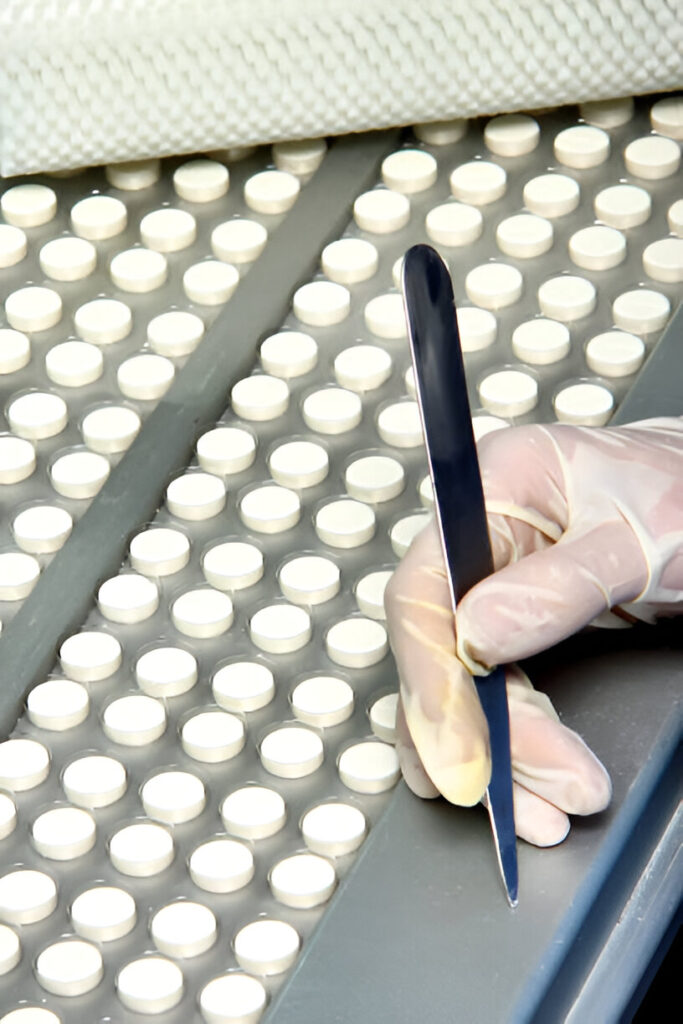

Advanced Technologies in Quality Control

Quality control technologies have undergone a significant evolution, enhancing precision, efficiency, and real-time monitoring in pharmaceutical production. These innovations ensure that manufacturers uphold rigorous quality standards while reducing human error and downtime.

Cutting-Edge Tools Used in Quality Control

- Real-Time Release Testing (RTRT):

RTRT enables manufacturers to test products during the production process rather than after batch completion. This real-time approach allows for faster identification of any quality issues.

- Process Analytical Technology (PAT):

This FDA-recommended framework helps monitor manufacturing processes using advanced sensors and data analytics. It allows real-time adjustments to maintain product quality.

- AI and Machine Learning:

Artificial Intelligence optimizes quality assurance by identifying trends, predicting issues, and preventing defects in production before they occur.

- Automation and Robotics:

Automating repetitive tasks like sampling and analysis not only improves precision but significantly reduces human intervention, which is prone to error.

Adopting these technologies empowers manufacturers to optimize their processes, reduce waste, and deliver consistently high-quality pharmaceutical products.

Training and Development for Quality Personnel

Even the most advanced technology is only as effective as the people using it. Human expertise is an indispensable element in pharmaceutical quality control, making staff training and development a key investment for any organization.

Building a Skilled Workforce

- Regular Training Programs:

Employees need continuous education on emerging technologies, regulatory changes, and best practices to stay updated.

- Certifications:

Programs like the Certified Pharmaceutical GMP Professional (CPGP) certification enhance employees’ credibility and skill levels.

- Cross-Functional Teams:

Collaborative teams from R&D, production, and QA foster a shared understanding of the importance of quality in the broader scope of the company’s mission.

By fostering a culture of continuous learning, companies empower teams to effectively manage the complexities of modern pharmaceutical challenges while ensuring compliance and quality.

Continuous Improvement and Innovation

Stagnation is the enemy of quality. Pharmaceutical companies must integrate a culture of continuous improvement to adapt to industry demands, regulatory changes, and evolving consumer expectations.

Tools for Continuous Improvement

- Kaizen:

Adopting the Kaizen methodology encourages ongoing, incremental improvements across all levels of operation.

- Metrics-Driven Decision Making:

Using data analytics allows companies to identify trends, optimize processes, and drive improvements in quality control.

- Feedback Loops:

Gathering input from patients, healthcare providers, and regulatory agencies helps uncover areas of improvement and innovation.

By prioritizing innovation and flexibility, organizations ensure they remain competitive in a fast-changing industry while continuing to deliver top-quality pharmaceutical products.

Conclusion

Achieving excellence in pharmaceuticals is no longer optional; it is a responsibility that serves both companies and society. From rigorous QA measures and regulatory compliance to adopting advanced technologies and fostering skilled professionals, maintaining top-tier quality requires a multifaceted approach.