Table of Contents

- Introduction

- Understanding Used Engines

- The Remanufacturing Process Explained

- Key Advantages of Remanufactured Engines

- Comparing Costs: Remanufactured vs. Used Engines

- Performance and Longevity Considerations

- Environmental Impact of Engine Choices

- Making an Informed Decision

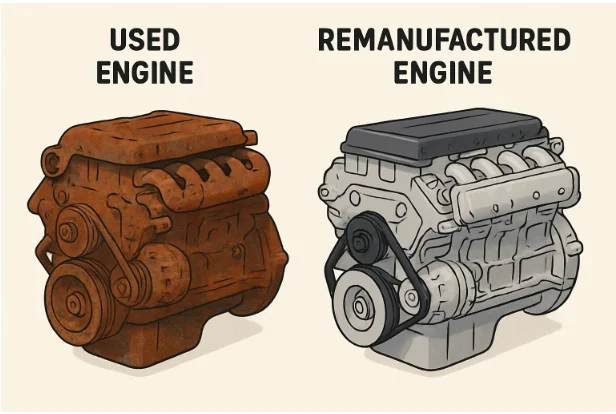

When your vehicle’s engine fails, your next step can profoundly impact your car’s reliability and your peace of mind for years to come. Many drivers are forced to choose between a used engine and a remanufactured engine. Understanding the distinctions between these two options is crucial for protecting your investment in your vehicle’s future performance and dependability.

Remanufactured engines are generally a better choice than used engines for drivers seeking performance and value. While used engines may seem cheaper initially, they carry hidden risks due to their uncertain history and wear. Remanufactured engines undergo a thorough restoration process, enhancing reliability and lifespan. By choosing a remanufactured engine, buyers benefit from quality control and engineering oversight that are often lacking in used engines.

Understanding Used Engines

Used engines are usually sourced from vehicles taken out of service due to accidents, age, or other issues. Their exact service history is rarely documented, making the integrity of internal parts, the quality of previous oil, and general maintenance unclear. These unknowns can spell trouble, as worn or neglected parts may fail without warning. Even meticulous vehicle owners looking to save money can fall victim to unforeseen breakdowns and costly repairs associated with used engines. As Consumer Reports outlines, transparency into service history and component wear is a major issue with any used powertrain component.

The Remanufacturing Process Explained

Remanufactured engines are not simply cleaned or cosmetically refreshed; they are systematically rebuilt to stringent specifications. The process begins by fully disassembling the engine, after which every part is cleaned, measured, and tested. Critical components such as pistons, bearings, valves, and seals are replaced or machined to meet or exceed original equipment manufacturer (OEM) standards. The result is a powerplant that performs like new, free from the hidden defects and wear that plague used engines.

This comprehensive restoration process is governed by strict standards, such as those outlined by the Automotive Parts Remanufacturers Association, further ensuring quality and reliability.

Key Advantages of Remanufactured Engines

- Enhanced Reliability: Remanufactured engines are built to address prior failures, correct potential weaknesses, and address chronic design flaws, often making them more reliable than new engines.

- Warranty Assurance: Industry-standard warranties, sometimes extending to multiple years or miles, back most remanufactured engines. This provides peace of mind that used engines simply can’t match.

- Environmental Benefits: Remanufacturing reduces landfill waste and conserves natural resources by reusing base materials—even as precision work ensures they perform to current standards. According to the U.S. Environmental Protection Agency, this contributes significantly to sustainability within the automotive industry.

Comparing Costs: Remanufactured vs. Used Engines

The price tag for a remanufactured engine is undeniably higher at the outset than that of a used engine. However, the equation shifts when factoring in the real-world cost of potential repairs, downtime, towing, or even another replacement. Remanufactured engines commonly lead to lower total cost of ownership over time due to fewer breakdowns and strong warranty protection. The peace of mind that accompanies a reliable engine and manufacturer support often outweighs the upfront savings of used options.

Performance and Longevity Considerations

Every remanufactured engine is painstakingly restored to, or above, OEM standards, whether by replacing worn parts or correcting original weaknesses. This leads to consistent, manufacturer-intended performance and a lifespan that can equal—or surpass—a factory-new engine. Used engines, in contrast, come with performance risks tied to previous neglect or high mileage and may already have hard-to-detect failures ready to emerge with regular use. For anyone counting on their car for daily transportation or long trips, this reliability gap is impossible to ignore.

Environmental Impact of Engine Choices

Choosing a remanufactured engine is a step toward environmental responsibility. Every powerplant restored saves critical materials and energy that would be spent building a new engine from scratch, while preventing usable engine blocks from becoming industrial waste. This sustainable choice aligns your repair decisions with ongoing efforts to reduce automotive pollution and resource depletion.

Making an Informed Decision

When it’s time to bring your vehicle back to life, carefully weigh factors such as reliability, warranty coverage, long-term value, and environmental impact. Remanufactured engines are not merely a replacement—they’re a renewal, backed by expert oversight and the confidence of strong manufacturer warranties. For lasting dependability and the best value, a remanufactured engine is the clear choice among modern drivers and automotive professionals alike.